Try Our Best to Cooperate with S/Y and Minimize Propeller Repair Term

Time of issue:

2023-06-25

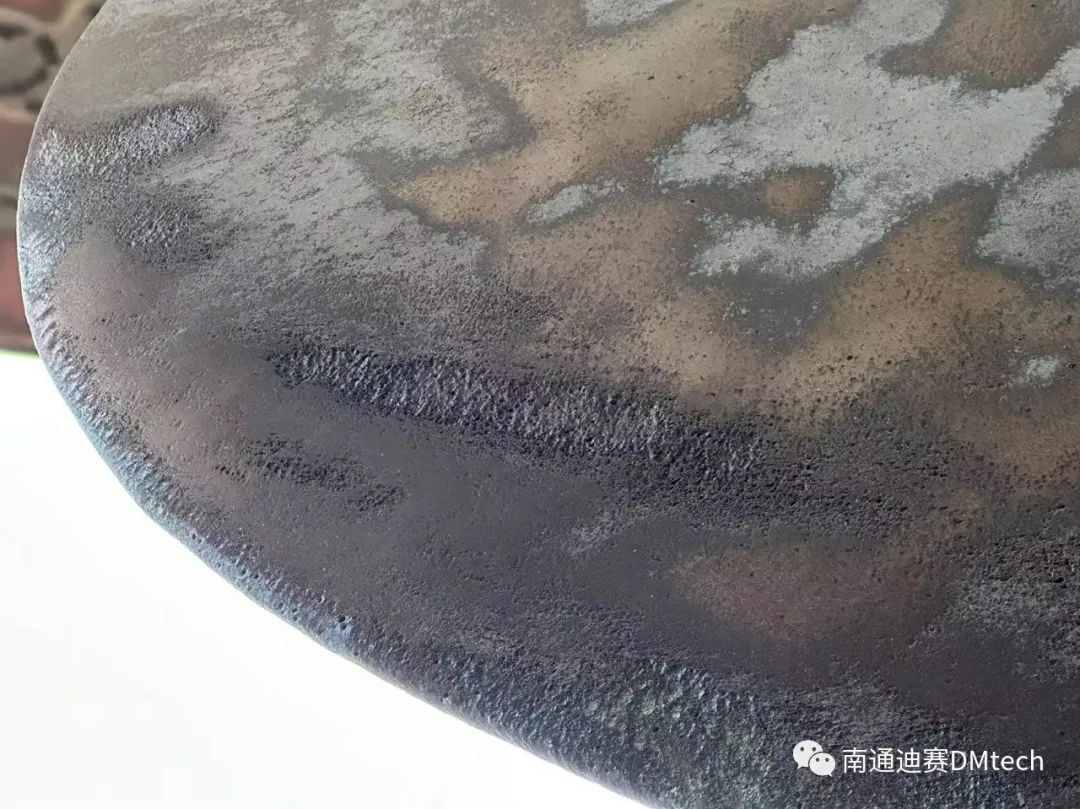

We completed the propeller repair of MV S**** in one day to cooperate with shipyard to control the dry-docking days. The propeller of MV S****, all four blades with serious cavitation corrosion and mechanical damages. The normal repair time is 2 days. But the shipyard docking planning is totally 5 days, and there are 1-2 raining days. We tend to put down the propeller as the big welding jobs. But shipyard apts to repair in site and it’s better just in raining day. As the service partner, we subordinate to owner’s dry-docking planning and try our best to cooperate with SRM. Our efforts satisfied both of ship repair team and site superintendent finally.

The propeller of MV S****, diameter 5200mm, Mn-Al-Bronze(Cu4), not the very popular Cu3 material. We are very careful of the welding and strictly control the interpass temperature during repair.

What’s the cavitation corrosion? When the propeller blades run in the water, the water will produce positive pressure on the pressure surface and produce negative pressure on the suction surface. The negative pressure change the gas to bubbles. These bubbles burst and impact the blade surface, leading to erosion. It’s cavitation corrosion.

Related news

Mobile

Diesel Maritech Nantong Co.,Ltd

Add:No.129, Xinsheng Road, Nantong

Contact:Ron Cheng Ligang Yu

Mobile:0086-13776909006 15370660922

Email:sales@dmtechnantong.com

Tel:0086-513-85252179/85252169

Fax:0086-513-85252169

Copyright © 2022 Diesel Maritech Nantong Co.,Ltd